CHEMICALS & PETROCHEMICALS

Work that involves chemicals/petrochemicals often requires protective clothing that is certified to EN 13034, EN 1149-5 and EN ISO 11612. It is also important to identify which chemicals the company uses, so that protective clothing can be chosen that is appropriate for the specific chemicals or group of chemicals that are in use.

RISK ASSESSMENT

- Splashes of chemicals

- Risk of explosion / ATEX-environment

- Heat & Flame

- Splashes of chemicals

- Traffic accidents (limited)

- Electric Arc (Industrial Electricians)

RISK EVALUATION

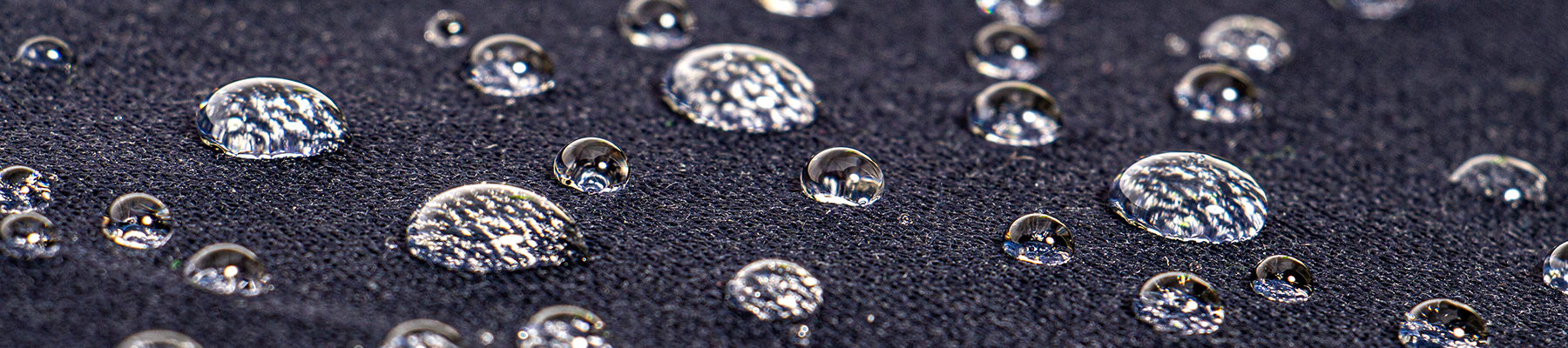

When working within the petrochemical industry, Tranemo recommends garments certified according to EN 13034, EN 1149-5 and EN ISO 11612. The Anti-Static properties of a garment minimise the risk of creating sparks (a source of ignition) which could cause an explosion. Most of the Tranemo FR fabrics are EN 13034 certified and have a treatment that protects against chemicals in spray form.

Garments that are suitable and have an approved design have the EN 13034 symbol in the CE-marking. It is important to choose the right fabric that passes the risk of the chemical group that is used within a business. These garments need to go through industrial laundry to reactivate and re-impregnate the EN 13034 finish.

In case of risk of an Electric Arc, you also need garments certified according to EN 61482-2. High Visibility EN ISO 20471 may also be of need if there is a risk from moving vehicles or where visibility of employess is important.

A MORE ENVIRONMENTALLY FRIENDLY CHOICE

If your company does not need protection against O-xylene or Butanol you can choose a fabric with a PFAS free finish. Tranemo’s PFAS-free finish passes EN 13034 for acid and alkaline.

Per- and polyfluoroalkyl substances (PFAS) are a diverse group of synthetic chemicals used in a wide range of consumer and industrial products. PFAS is used for its good resistance to grease, oil, water and heat, but is a poor environmental choice. Tranemo works hard on phasing out PFAS where it is not necessary, developing new ranges with PFAS-free finishes.

We also see the need for a strict chemicals legislation to minimise and eventually end the use of PFAS. In 2021 we joined the Chemsec’s Corporate PFAS Movement - ”No to PFAS” to influence the way chemicals legislations are implemented in practice.

A PFAS-free finish does not contain any fluorine atoms which is very difficult for nature to break down. This makes a PFAS-free product a better and more environmentally friendly choice.