LESS CHEMICALS

We aim to ensure that our garments are free from harmful, prohibited or restricted chemicals. By signing Tranemo Acceptance Document, our suppliers are obliged to follow the requirements and restrictions accordingly. Use of chemicals is sometimes necessary in our product development. Our main purpose is to protect our customers from serious flame related injuries and to develop the best protective solution in a sustainable way. Therefore, chemicals must be handled carefully to ensure that our products are safe for consumers and for the environment.

100% Inherent Flame Retardant Workwear

Tranemo only manufactures inherent Flame Retardant workwear which guarantees lifelong Flame Retardant protection for the wearer. The Flame Retardant properties lie in the molecular structure of the fibres and cannot be washed or worn out. Other benefits include comfort, durability and the use of lightweight fabrics, in addition to offering permanent Flame Retardant protection. Tranemo works closely with fibre manufacturers, and we are always ready for new innovations and more sustainable development.

Reach

Tranemo products are made from fabrics and accessories that meet the requirements of REACH. REACH is an EU regulation on chemicals legislation and the abbreviation stands for: Registration, Evaluation, Authorisation and restriction of Chemicals. ECHA is the European Chemicals Agency, and in Sweden the Swedish Chemicals Agency has primary responsibility for applying the REACH regulation.

Restricted Substance List (RSL)

To ensure that ourproducts meet all the requirements of REACH, we use a Restricted Substances List (RSL) which all our suppliers must sign and comply with. The Tranemo RSL is a list of all substances and the requirements and limit values under European legislation. In addition to REACH, Tranemo uses its RSL to comply with all current EU regulations, such as the Persistent Organic Pollutants Regulation (POPs) and the Biocides Regulation. Our RSL also allows us to ensure that our suppliers comply with the Candidate List for substances of extremely high concern (SVHCs).

The Swedish Chemicals Group

Tranemo is a member of the Chemicals Group at RISE IVF, which means we can keep up to date with the latest developments in research and legislation. In collaboration with RISE, the Tranemo RSL is updated twice a year to ensure that we comply with restrictions and updated legislation as recommended by the Chemicals Group.

Standard 100 by OEKO-TEX®

Product tested for harmful substances

Nearly all of fabric and accessories that TRANEMO uses are tested and certified under OEKO-TEX Standard 100, product class 2. OEKO-TEX is an independent third-party certification process that ensures control of harmful substances. By using Standard 100 we mitigate the risk of unintentional use of harmful substances, increasing safety for end users.

When a garment is certified according to Standard 100, every component of the garments, including fabric, lining, buttons and sewing threads, is tested for listed harmful chemicals according to required documents. These documents include limit levels for over 300 substances, which is based on substances prohibited and restricted in EU (REACH) and national laws together with substances scientifically proven to be harmful to health.

Since PFAS sometimes is required to keep wearers safe in certain highly demanding work environment, PPE garments containing PFAS can be certified under OEKO-TEX Standard 100 Supplement PPE, which exempts PFAS and a few other chemicals. TRANEMO is actively working to phase out PFAS in all workwear where it is not essential, with the goal of maintaining only one PFAS-containing range for chemical workers (Range APEX), certified under the OEKO-TEX Standard 100 Supplement PPE.

PFAS-free workwear

Per- and polyfluoroalkyl substances (PFAS) are a diverse group of human-made chemicals used in a wide range of consumer and industrial products. PFAS are resistant to grease, oil, water and heat. Some PFAS have been more widely used and studied than others.

By 2025, Tranemo will exclusively source PFAS-free fabrics, with one exception. The fabric retained with PFAS impregnation is used in the Apex range, designed to protect against chemical splashes from oil, O-xylene, and butanol. Unfortunately, no suitable alternative has yet been identified to safeguard against these specific hazards, and in this case, our priority must be to keep you safe at work. Many of our ranges are naturally PFAS free and others are treated with a PFAS-free treatment.

We also see the need for a strict chemicals legislation to minimise and eventually end the use of PFAS. Since 2021, we have been part of the Swedish non-profit organization ChemSecs ”No to PFAS” movement to influence how chemical legislation is implemented. An important work that we are proud to be a part of.

» Read more about our work with PFAS

Cross-Impregnation

For workwear with chemical protection compliant with EN 13034, re-impregnation after washing is necessary to maintain protective properties. Through extensive testing, we verified that cross-impregnation in both directions preserved the water and chemical repellence of all products, ensuring continued compliance with the EN 13034 standard regardless of the chosen finish. A result that is perfect for the phase out of PFAS.

Our decision to phase out PFAS was facilitated by ensuring that cross-impregnation is achievable both ways. Cross-impregnation means that a fabric with a PFAS finish (C6) can be re-impregnated with a PFAS-free finish (C0), and the other way around. After a lot of tests our conclusion was that the fabric does not lose its function and still pass the standard for EN 13034 Type PB[6] despite the cross-impregnation. This result made our decision to phase out PFAS where it is not necessary easy.

Cross-impregnation and laundries

Washing and re-impregnation should always be carried out at industrial laundries equipped to perform the process correctly within a closed system. As cross-impregnation is possible, laundries do not need to separate PFAS-free garments from the ones that contain PFAS. In addition, this also means that laundries have the possibility to choose whether they want to use a PFAS or a PFAS-free re-impregnation on workwear certified for acid and alkaline. A big step towards a PFAS-free future.

Finish with or without PFAS

The result also means that our customers have a choice if they want to become PFAS-free before all the stock garments become fully PFAS-free. If your company’s risk analysis indicates a need for protection only against acid or alkaline, you can choose a fabric with a PFAS-free finish. A PFAS-free finish does not contain the fluorocarbon bond that does not breakdown in nature, which makes the PFAS-free products a more environmentally friendly choice. If your company requires protection against O-xylene or butanol, you need a garment with a fabric with a PFAS finish. As a customer, you can always ask for a PFAS-free re-impregnation on your garment or ask for a garment without any finish - just make sure you know what type of protection you require.

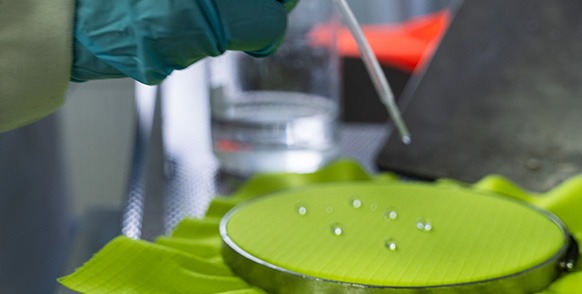

Examin your PFAS-free workwear

To confirm that a garment’s water and chemical repellence remains effective, Tranemo recommends conducting random sampling on your workwear.

This can be done easily using a droplet test.

Place a droplet of vinegar on the fabric.

■ If the droplet does not absorb, the repellent function is working, and your protection is in good condition.

■ If the droplet absorbs into the fabric, the repellent function is not working and a re-impregnation or a re-activation by heat is needed.